Hand-held Foam-in-Place Packaging System

Product Introduction

Equipped with accurate electric metering pumps,sensitive temperature monitors,excellent self-diagnostic device,Easypacker series systems can guarantee top quality polyurethane foam atevery shot.

Conformity to Safety and Environment Regulations:

1.Easypack systems are CE certified.

2.ROHS testing reports are available for packaging materials.

3.NOCFC,guaranteed.

4.Easypak recycling network has been set up.Once cushions are received,we promise to recycle them,or send them to energy recovering incinerators.

Advantages of products

1. Electric metering pumps to ensure continuous feed pressure and provide precise mixing ratio of raw materials; each electric metering pump is connected via a cable to the host computer, so that it can maintain the necessary communication between pumps and the main control to ensure that equipment can normally function.

2. Electric-controlled spray gun equipped with a patented self-cleaning muzzle will increase the life of its usage.

3. Integrated microcomputer control system is designed to be self-diagnostic and monitor device status. Easy identification indicator displays the operating status of the system; metering timer mode can be set to adjust the amount of raw material.

4. Bilateral independent temperature control, each line has a heating thermistor. Each thermistor can communicate with the controller, which provide separate temperature control for each raw material.

Equipment supporting supplies

1. the foaming materials

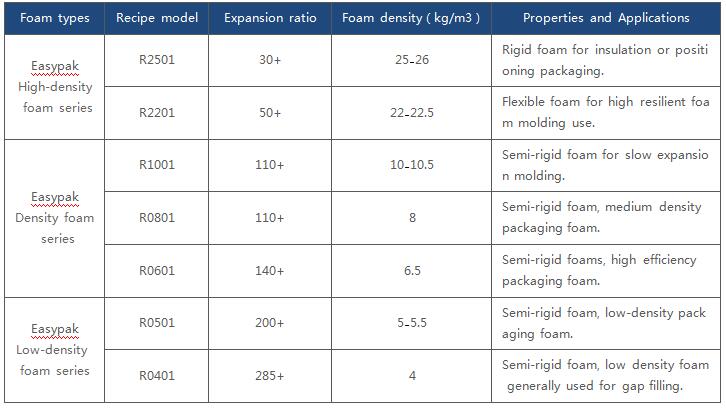

Polyurethane foam using A / B two materials were mixed to react. Response to different strength and characteristics of the foams for different packaging needs, Han Yin provides the following formulas:

2. film for foaming

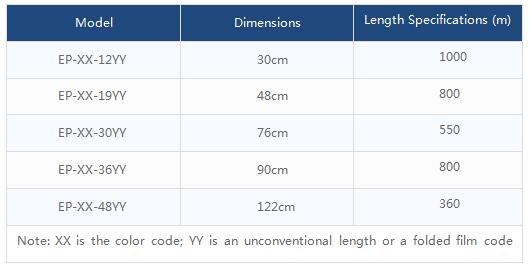

Either the formula or extrusion process conditions of our films are specially developed far better than the general strength of polyethylene film, to ensure that during the foaming reaction and subsequent use the films are tough, durable, and unbreakable. We offer different sizes of Easypack film rolls as following, corresponding to different sizes of packaging foams and different equipment.

Operation instructions

Foam-in-Place packaging steps:

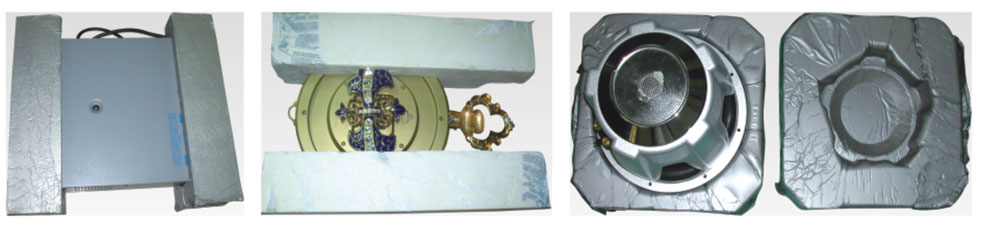

1. Trigger dispenser to mix the chemicals into the box paved with film.

2. Fold the film in place and place your product right on the expanding foam.

3. Pave another film over your product, and then refill the chemicals, fold the film, and close the box.

4. While instant foam is completed, your product is surrounded and protected by two sets of foams up and down.

Preformed molding:

1. Use prefabricated simple wooden mold to produce a specific shape of the foam bag.

2. The film will be the first paved in the mold cavity. Then, inject the chemicals, infold the film and close the wooden box, a foam bag will be completed instantly.

Product operation video