Automatic Foam-in-Bag Packaging System

Product Introduction

Our Fastpacker? equipment is a fully automatic, foam-in-place packaging device that automatically generates a foam bag while you press a button. At the same time, the device can produce up to 20 foam bags per minute to meet the high-volume production. On the basis of the functions with a hand-held foam packaging system, the customer can not only simply set the bag size and foam filling quantity through the man-machine interface, but also to set one single bag production and the time interval, or multiple bags production. In addition, the customer can also set continuous tubular foam mode. The size of the tubular foam and their arrangement can be adjusted.

Compliance with safety and environmental requirements:

Equipment with CE certification.

Provide raw material SGS test reports related to hazardous substances, and road, sea transportation of general cargo testimonials.

Using water as the blowing agent, prohibit the use of elemental fluorine materials.

Establishment of recycling spots nationwide.

Product advantages

Production and application of continuous tubular foams:

1. It can be programmed to set the size and number of tubes.

2. It is used for bottom cushioning, space filling and wrapping products.

3. IT can be centrally produced, and then distributed to many packaging lines for use.

Equipment supporting supplies

1. the foaming materials

Polyurethane foam using A / B two materials were mixed to react. Response to different strength and characteristics of the foams for different packaging needs, Han Yin provides the following formulas:

2. film for foaming

Either the formula or extrusion process conditions of our films are specially developed far better than the general strength of polyethylene film, to ensure that during the foaming reaction and subsequent use the films are tough, durable, and unbreakable. We offer different sizes of Easypack film rolls as following, corresponding to different sizes of packaging foams and different equipment.

Operation instructions

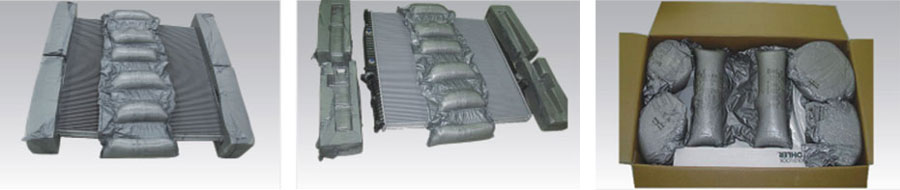

Single Foam Bag Packaging Steps:

1. The operator selects the size of the foaming bag and the filling amount of the raw material, and presses the set parameter group to automatically generate a foam bag.

2. Place the foam bag into the box and place the product right on the expanding foam bag.

3. Make another bag, place it on top of the product, and close the carton again.

4. Wait for the foam to complete, your product is then surrounded and protected by two sets of foams up and down.

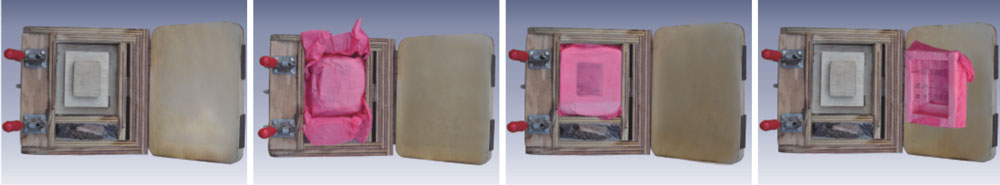

Preformed molding:

1. Prepare the prefabricated mold.

2. By using air suction device, the foam bag will be attached into the cavity of the mold and foam bag will expand quickly and form the shape according to the cavity shape..

3. After completion of the reaction, use the hair device to help the foam bag remove from the mold cavity.

4. Tailored to provide economic, efficient, uniform protection.

Product operation video